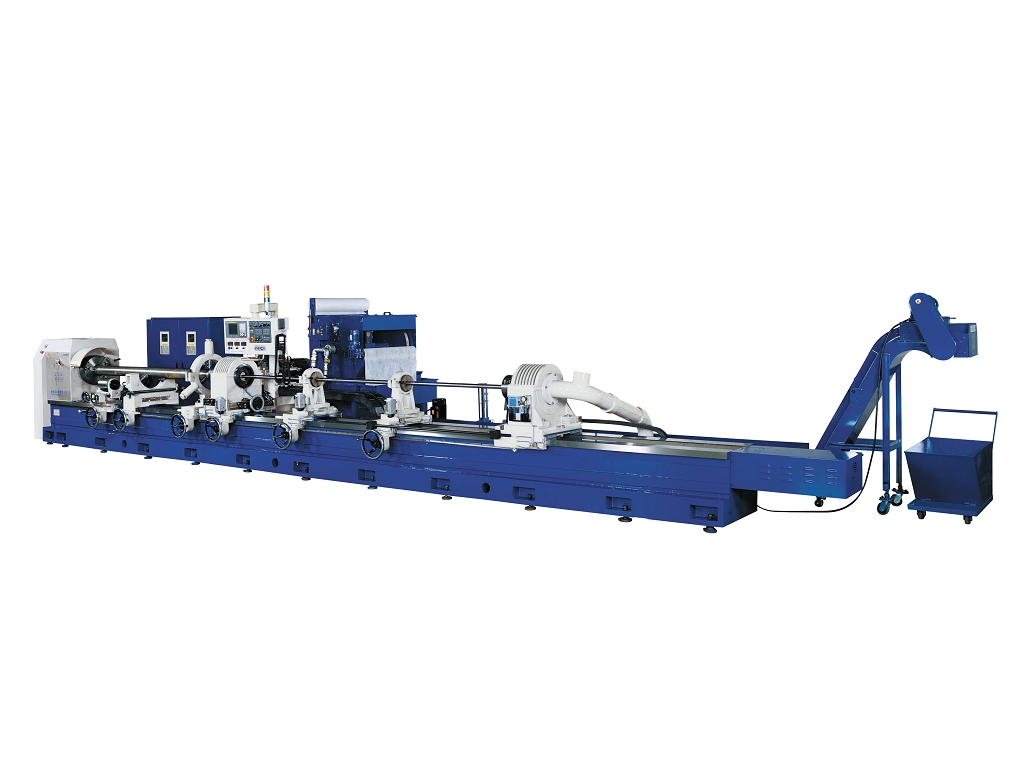

Product

ELA-2000-3000-4000

Product Description

1. Shafts can be machined by applying BTA technology deep hole drilling to upgrade efficiency and accuracy. Drilling capacity is 30 to 200 mm with maximum depth up to 5000mm (model ELA), 11000mm (model ELB).

2. This model is rotating workpiece, in addition, it divides cutting tool into no rotation type and rotation type (opt.), ensuring increased accuracy.

3. The machine employs a FANUC 0i-T CNC controller for easy operation. Equipped with a torque detection function. Cutting tool will retract in case of damage. And drilling a workpiece with hard to break chips, the intermittent drilling function will facilitate chips breaking, which can’t be achieved on conventional machines.

4. Two box ways on the machine bed features maximum rigidity of structure. This provides heavy cutting resistant performance and excellent heavy loading capability.

5. All casting parts are manufactured from FC-30 high quality cast iron, and are tempered for deformation-free.

6. The headstock is designed with two-step (model ELA) and 4-step (model ELB) manual speed change combined with heavy module-6 gears, making the machine ideal for heavy cutting. A vector type frequency inverter features uniform spindle speed destruction, that enables the machine to fully develop its machining performance.

7. The headstock for ELB has removable design for changing workpiece length conveniently, matching bar length to fully develop its machining performance.

8. Z-axis is correctly located at the center of bed for uniform loading. Transmitted by precision ball screw with minimum backlash and long service life.

9. An automatic lubricator is mounted at the tool clamping mechanism and Z-axis ball screw position for forced lubrication.

10. All equipment are mounted on the floor for convenient installation. No need to dig into ground for installation to save installation costs.

2. This model is rotating workpiece, in addition, it divides cutting tool into no rotation type and rotation type (opt.), ensuring increased accuracy.

3. The machine employs a FANUC 0i-T CNC controller for easy operation. Equipped with a torque detection function. Cutting tool will retract in case of damage. And drilling a workpiece with hard to break chips, the intermittent drilling function will facilitate chips breaking, which can’t be achieved on conventional machines.

4. Two box ways on the machine bed features maximum rigidity of structure. This provides heavy cutting resistant performance and excellent heavy loading capability.

5. All casting parts are manufactured from FC-30 high quality cast iron, and are tempered for deformation-free.

6. The headstock is designed with two-step (model ELA) and 4-step (model ELB) manual speed change combined with heavy module-6 gears, making the machine ideal for heavy cutting. A vector type frequency inverter features uniform spindle speed destruction, that enables the machine to fully develop its machining performance.

7. The headstock for ELB has removable design for changing workpiece length conveniently, matching bar length to fully develop its machining performance.

8. Z-axis is correctly located at the center of bed for uniform loading. Transmitted by precision ball screw with minimum backlash and long service life.

9. An automatic lubricator is mounted at the tool clamping mechanism and Z-axis ball screw position for forced lubrication.

10. All equipment are mounted on the floor for convenient installation. No need to dig into ground for installation to save installation costs.

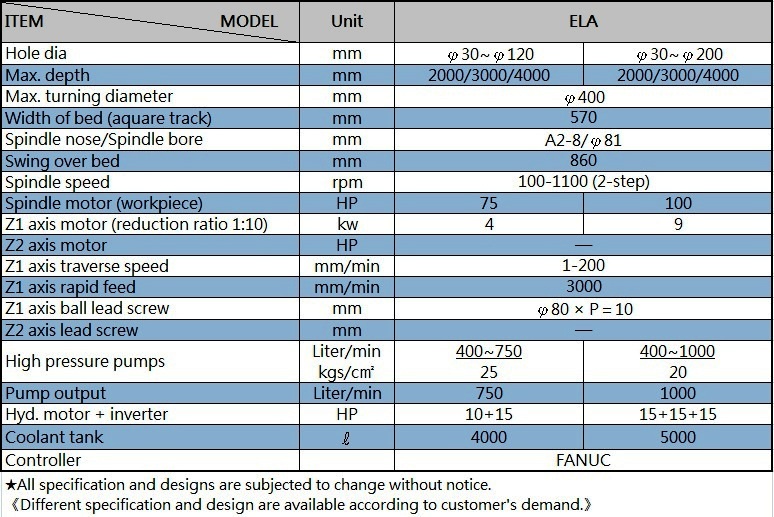

Product Specifications

| ■ Standard Accessories | ■ Optional Accessories | |||

| 1 | FANUC 0i-T controller | 1 | Tool rotating headstock | |

| 2 | High & low pressure coolant pump | with rotatable type workpiece supporter | ||

| 3 | Automatic lubricator | 2 | Roller type workpiece supporter | |

| 4 | 16" 3-jaw strong-type scroll chuck | 3 | Boring head & drill tube | |

| 5 | Guide bush for deep hole drilling (P.H) | 4 | 4-jaw chuck | |

| 6 | Paper filter unit | 5 | Pressure head with chuck | |

| 7 | Chip conveyor | 6 | CE/CSA approval specification | |

| 8 | Coolant cooler | 7 | Chip oil-extractor | |

| 9 | Tools & tool box | |||

Back